As winners of the Prime Advantage Innovation Awards, Kloeckner Metals continues to improve and expand its Part Manger tool for ordering steel online. The tool has been expanded to serve more groups, and new features have been added to better serve customers. A tool which started as a small pilot program has now grown to serve a variety of different contract customer groups. The new consignment feature further expands the reach of the product.

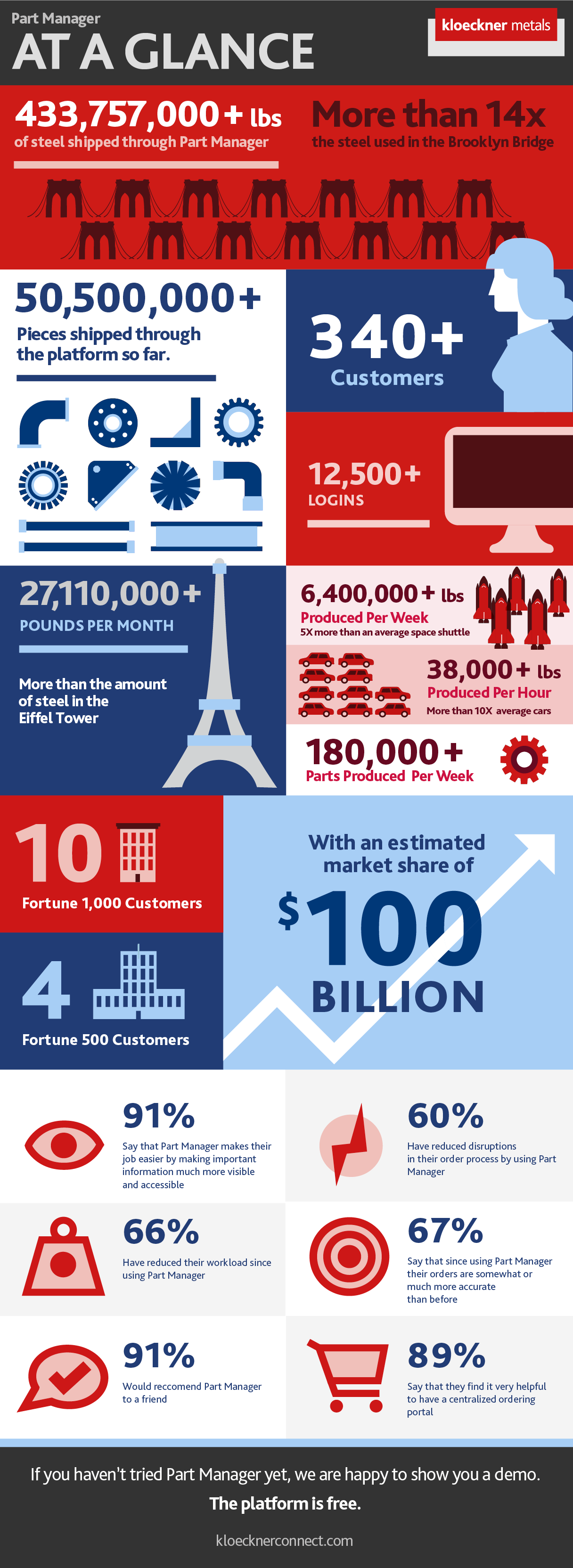

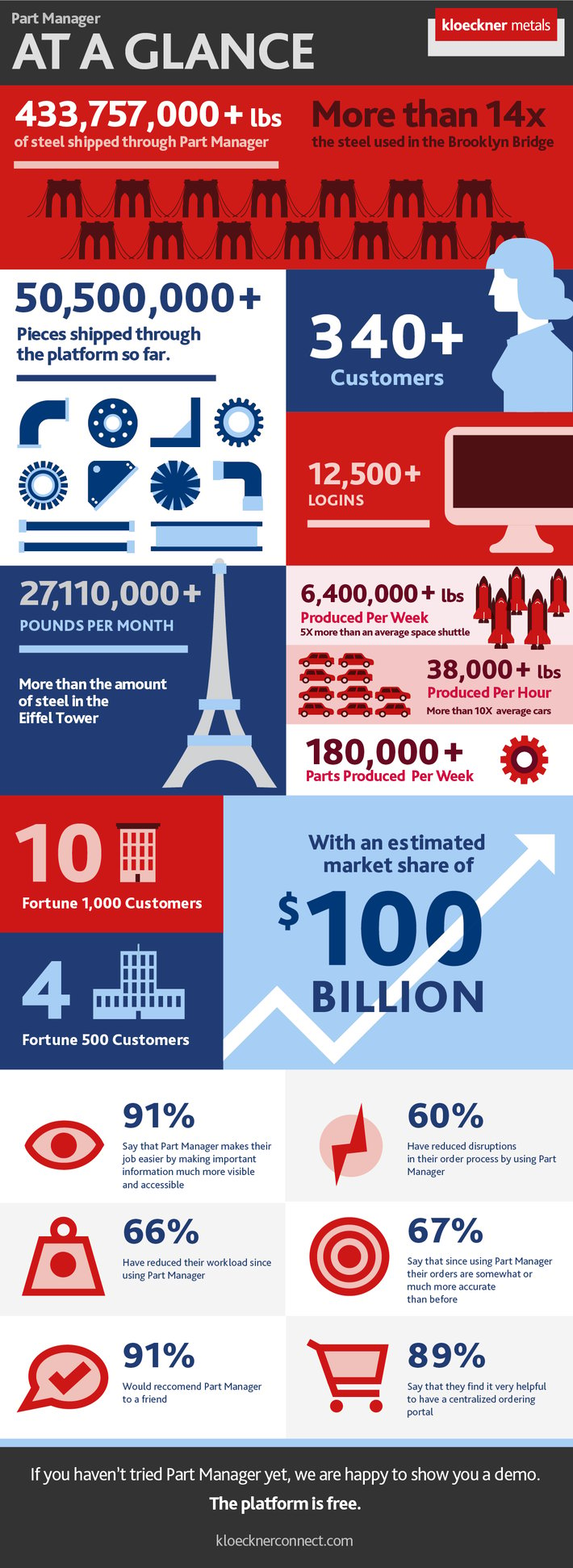

“Not only number of customers, but a number of users and obviously the sales dollars that are now being transacted over the tool are pretty impressive,” says Amy O’Stean, Sr. Business Product Manager at Kloeckner Metals.

The customer response has been overwhelmingly positive. Adoption is high, and customers are overall very happy with the product. Still, Kloeckner has been trying to find ways to improve it. Customer feedback is a prime driver of these improvements. Ultimately, new improvements and features are created primarily to meet specific customer demands.

“We have territory managers who are primarily out visiting customers week in and week out,” Amy says. “If it’s a Part Manager customer, a point at every customer visit is to ask how it is going. We encourage those folks to give us feedback and pass on any information they get, any kind of request, or problem.”

In making new features, there is a balance between applicability and complexity that needs to be kept. A relatively simple improvement that only applies to a small subset of customers might happen sooner than an improvement that will serve a wide range of customers but is very complex and difficult to implement.

“It’s a give and take between those two factors: complexity and applicability,” Amy says.

One example of a feature that was created to meet specific customer feedback is the quick access label feature. This allows customers to create organizational labels in any way they would like. For example, a customer could create a favorites list of their most frequently ordered parts. They could also use it to designate the internal product group ordering it, or the location where the part will go.

“Instead of building those things separately we asked if there was a way to combine all this in one feature and give the customer a really flexible way to label it however they want,” Amy says.

Another feature is for customers who use blanket POs. These are used to cover parts that are purchased over and over again. Instead of having to key in all the details each time the part is ordered, Part Manager will auto populate the applicable fields for customers with blanket PO agreements.”

“It is so the buyer doesn’t have to constantly enter in a PO for today, and another one tomorrow, and another one the next day,” Amy says.

The new consignment feature is targeted at a specific subset of customers, but for them, it has been extremely helpful. Consignment is where customers order and ship material, but they are not invoiced at that time. Instead, Kloeckner continues to own the material even though it is physically on the customer’s floor. When the customer uses the material, they then report that back and Klockner sends an invoice at that time. This allows certain customers to better control their working capital.

To serve these customers, Kloeckner created a queue in Part Manager which allows customers to manage the consignment program. In the past, the information may have been logged into an Excel spreadsheet which was traded back and forth between the customer and sales representative. Now the customer can just go into Part Manager and take care of it with a few clicks.

“It only works for a very specific sales arrangement, but for those customers they love it,” Amy says. “They see it as much more efficient.”

Part Manager also has a major upgrade in the works in the form of Part Manager 2.0. This will be a major overhaul of the Part Manager back end. When it is first rolled out, it will have almost identical features. The front end feel might be a little different and have a different look, but the big changes are going to be on the back end of the system. This will allow new features to be rolled out faster in the future.

“The main thing about Part Manger 2.0 is that we are trying to move from the beginning stages of this tool to an infrastructure that is more scalable and better prepared to handle feature enhancements in the future,” Amy says.

![]()

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: